What Are Pre-fabricated Wooden Frame Houses?

Pre-fabricated wooden frame houses are commonly made of timber frames. The components of the house undergo a prefabrication process in a production facility and are brought to the site for fast assembly. This type of structure is common in the United States, Europe, Australia and Asia.

Advantages of Pre-fabricated Wooden Frame Houses

Prefab wooden houses hold many advantages:

Fast and Easy Construction

With prefabricated wooden frame houses, all elements are produced in a factory and brought to the site for fast assembly.

Ability to Customize Existing Design to Meet the Client’s Preferences.

Since prefabricated wooden houses are produced using elements, the walls, frame, roof and floors can still be customized at the client’s request. Additional sections can be accommodated prior to assembly. For concrete houses, once the foundations are laid, it is very hard to customize it.

Energy-Efficient

Prefab wooden frame houses have great insulation value, and producers of these types of homes ensure that they will be perfect for any climate. They trap heat, making it warmer inside for a longer period, so there is no need to use heaters on colder days. In warm or hot seasons, wooden houses keep the interior cool. Thus there is less need for air-conditioning. These qualities of wooden houses are very significant in reducing energy consumption.

Longer Lifespan and Unchanging Property Value

A house with a good wooden frame can be expected to last up to a century, and as the same is true of prefab wooden houses. Since all of the elements are built in a dry, moisture-free, controlled environment, they are sure to last for many generations. This is also a factor in the unchanging property value of a wooden frame house, since it is able to be lived in for a long time.

Our main objective lies in offering high-quality, economical house packages with client-oriented service and prices using modules produced under known trademarks. Our company considers the speed and quality of the service we provide to be very important.

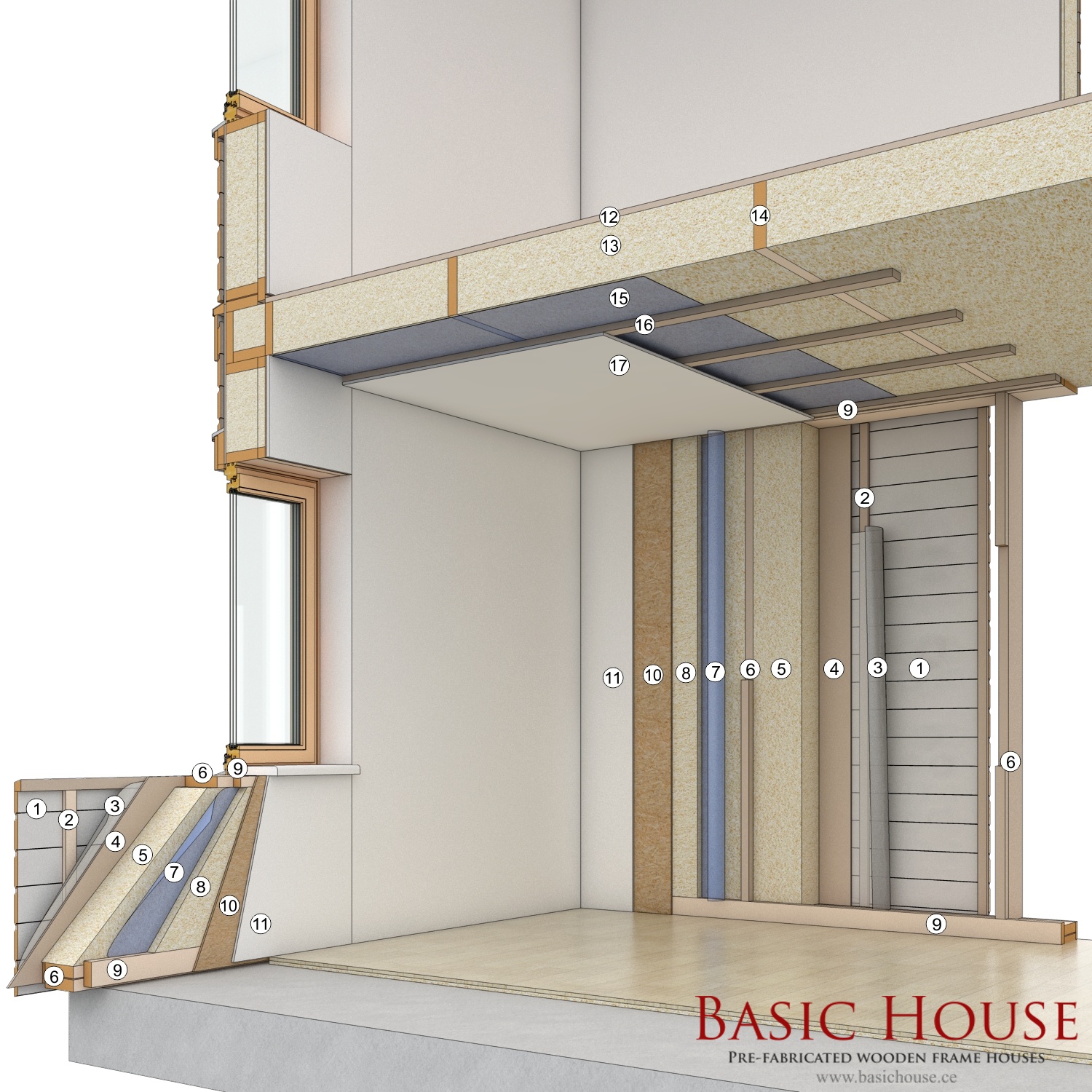

1 Wooden Boarding

2 Wooden Laths

3 Wind protection membrane

4 Wind Barrier Gypsum Board

5 Mineral Wool Insulation

6 Wooden Frame

7 PE-foile

8 Mineral Wool Insulation

9 Wooden Laths

10 OSB Board

11 Gypsum Board

12 Chip board

13 Mineral Wool Insulation

14 Wooden Battens

15 PE-folie

16 Wooden Laths

17 Gypsum Board

Basic House Technology vs Environmental Factors

Basic House’s main goal in building prefabricated wooden structures is to create passive houses that guarantee security and ease of living for our customers. It is our responsibility to ensure that all of our houses and structures have the ability to endure environmental factors so that every structure we build lasts for as long as possible.

Therefore, with skilful planning and strict implementation, we carefully put together layers of materials that effectively ensure the qualities of a good wooden structure listed hereunder.

Sustainable

We use timber frames in the fabrication of house elements. Timber structures are renewable and have the ability to coexist with nature without posing any harmful threat to the environment. Since timber frames are easily replenished, nature is preserved and future generations are not compromised.

Energy-Efficient

All of the materials we use in producing roof, ceiling, floor and wall elements work in harmony to help reduce energy consumption. Wooden houses adapt well to different weather conditions and have better insulation compared to steel and concrete. This eliminates the need to use cooling or heating.

Passive Fire Protection

We make sure that each membrane is protected and heat proof. Prefab wood houses uses technology where heat transfer is reduced layer after layer to prevent fire damage.

Promoting Healthy Living

It has been proven that people who live in wooden houses are more healthy than those who live in concrete homes. Timber homes have the ability to regulate air and filter it, allowing fresh breathable air and a controlled temperature inside.

How Basic House’s Passive Homes Work

Passive houses are considered the houses of the future. They promote energy efficiency and reduce impact on the environment. They have the ability to support themselves naturally so that they only require low energy consumption. This is one of the best ways of saving Mother Nature. A passive house can be equivalent to the numbers of earth hours that the world observes. If one passive house can make a significant change in the improvement of the ecosystem, how much more if most people entertain the option of having passive houses (such as prefabricated wooden frame homes) for themselves?

Now we know what are passive houses are. But, how do they actually work?

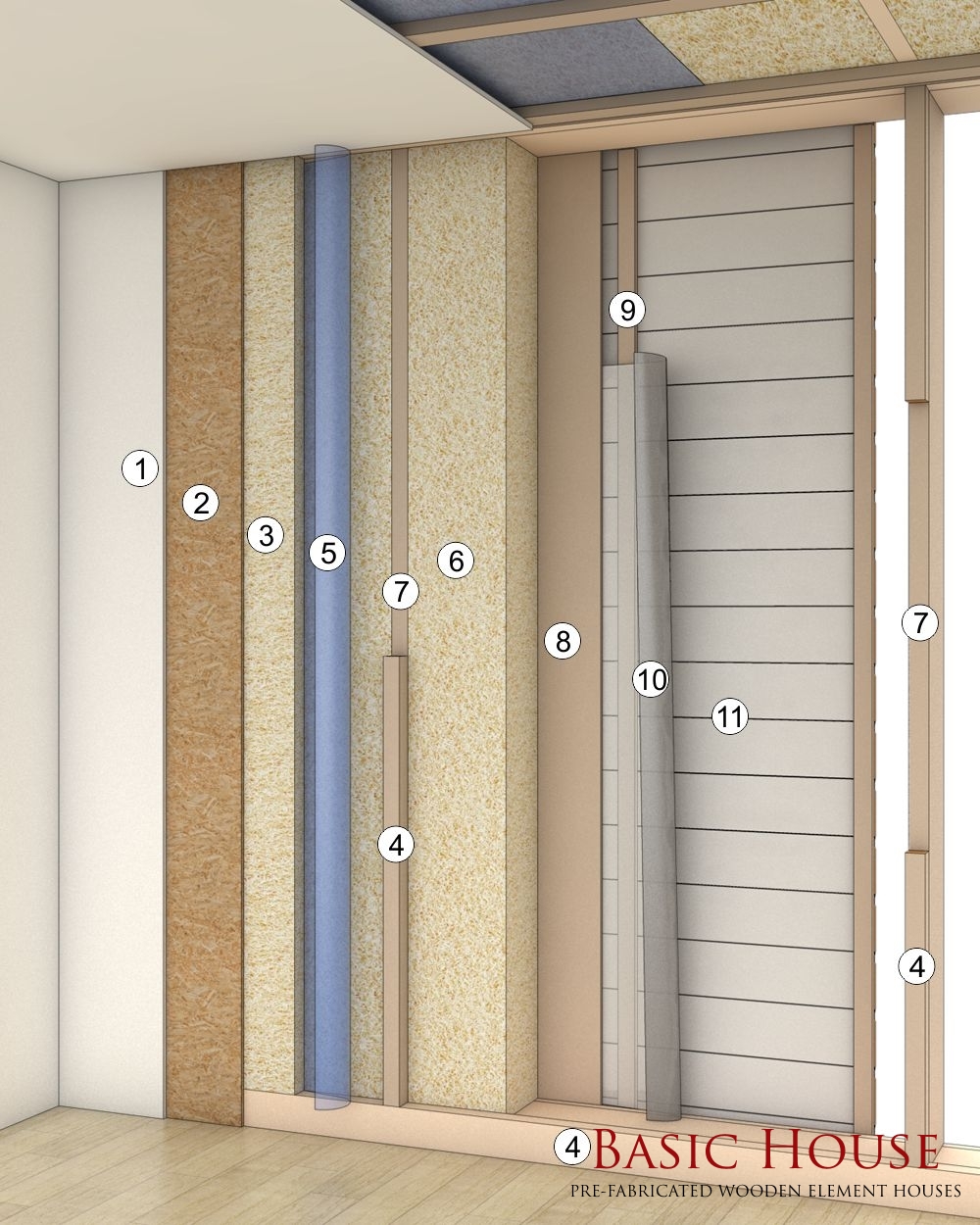

Below is an example of Basic House’s technology in creating prefabricated wall elements for all our standard designs. All membranes or layers work together to form a strong and durable wall, and the same is true of the roof, ceiling and floor.

1 Gypsum Board

2 OSB Board

3 Mineral Wool Insulation

4 Wooden Frame

5 PE-foile

6 Mineral Wool Insulation

7 Wooden Frame

8 Wind Barrier Gypsum Board

9 Wooden Laths

10 Wind protection membrane

11 Wooden Boarding

The above illustration shows all of the factors that may affect a house element and how each membrane work together to resist heat and cold.

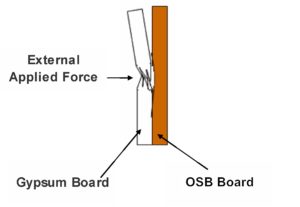

This illustration shows the main function of chipboard in making every element strong when added as a membrane. It is systematically placed between gypsum board and mineral wool insulation to prevent further damage if an external force is applied to it. OSB Board absorbs force and can endure bumps.

With many years of experience in the production and installation of prefabricated wooden frame houses, Basic House’s technology in this industry has developed high-quality prefabricated timber structures all over Scandinavia. Our exceptional service represents a high level of professionalism and expertise among our staff and trusted partners.

Wood tends to contract or expand when subjected to humidity and changing weather conditions. All of our lumber and timber is kiln-dried and planed prior to assembly. This is important in guaranteeing that all of the wooden materials used in the fabrication of elements have less movement once exposed outside during installation.

All timber materials are packed properly to avoid exposure to humidity and other environmental factors and are made ready for the fabrication process. Only good-quality lumber is used.

Build a wonderful life with Basic House!

Let us know what you need and we will gladly be of service!